SITUATION

The ADNOC Tower is located on the Abu Dhabi Corniche and consists of a 75-storey office tower and two levels of basements. The overall building height is 343 m with a gross office area of 160.000 m2. At the top, a large void is framed with a 67m sky bridge supporting a helipad.

The project started in May 2010 and will be completed in August 2017. Once the building is completed it is earmarked to be one of the major landmarks along Abu Dhabi’s Corniche.

CHALLENGES

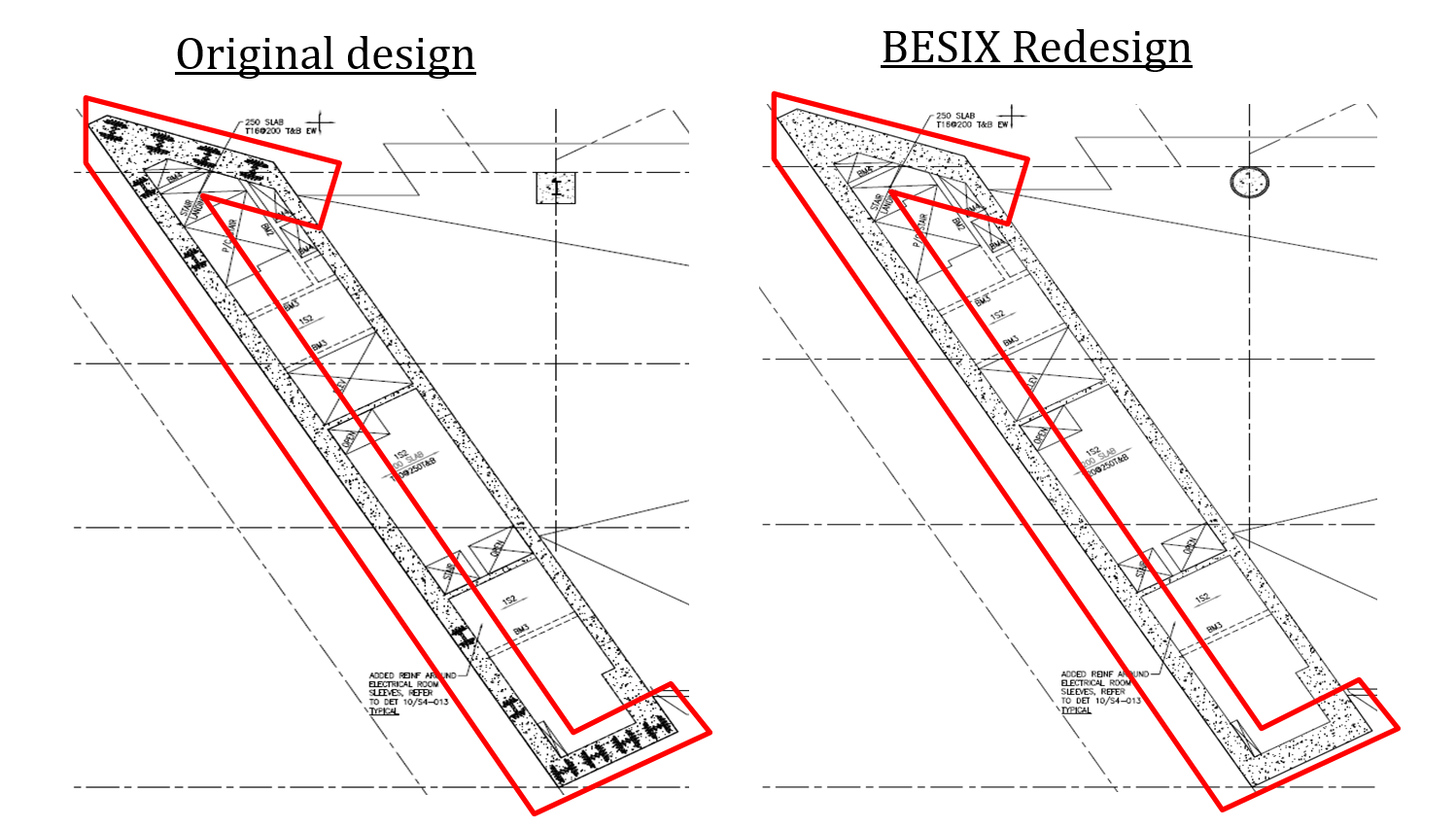

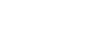

Many challenges were identified while studying the tender documents. Indeed, the original design called for numerous and heavy steel inserts in the columns and the core walls. Those steel inserts were not only costly but they made the construction more complicated. Post tensioning was required in the concrete slabs, which was impacting the execution planning. Finally, it appeared clearly that the construction of the helipad sky bridge would call for innovative solutions. Combined with a tight planning, only deep modifications of the original design could ensure a safe execution within the requested timeframe and budget.

SOLUTION

By using different materials and design codes than those specified in the tender documents together with appropriate construction technics Six Construct has been able to reduce significantly the quantity of steel in the structure. Using higher steel and concrete grades together with a rearrangement of the column cross sections led to a more convenient solution.

Using local expertise and technology, slabs posttensioning was also cancelled leading to a more economical design, easier to execute.

Six Construct developed a unique and spectacular strand jacking method for the construction of the helipad sky bridge. The decision to jack the 1050 tons structures from ground to their permanent positions at 342m was the brainchild of Dubai Engineering Department in a bid to optimize the structural design of lower floors while maintaining the roof construction program and reduce tower crane requirement to the minimum.

The alternative idea was to build the roof structure at L64 and jack it up by 47m but this meant commencement of steel works could only be started on completion of said level, with the slabs propped for 15 levels and therefore hindering other activities including block work, MEP, façade and resulting in an overall delay and more work at height.

RESULT

All the above changes contributed to improve the buildability and allowed the saving of 9000 Tons of steel in the core walls and 1500 Tons in the columns. To give an order of magnitude of these last figures, it is more than the overall tonnage of steel used for the roof of the 60,000 seats King Abdullah Sport City Stadium in Jeddah.

Beyond economical benefits, the alternative design proposed by Six Construct was safer to execute by limiting the handling of heavy elements as well as complicated welding operations at heights.